Converting Plastic to Fuel

Feb-13-19

A new technology that converts plastic to fuel could help reduce waste and slow resource use.

Feb-13-19

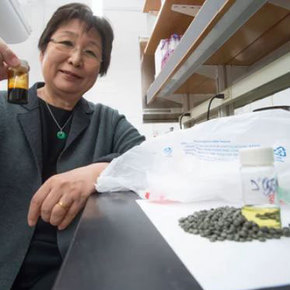

A new technology that converts plastic to fuel could help reduce waste and slow resource use.Developed by a team from Purdue University, the technology relies on hydrothermal liquefaction: converting materials to oil by heating them at moderate temperatures under high pressure. In this case, the team used the common plastic polyolefin, converting 91 percent of it into oil that could be used as a clean fuel source and replace up to four percent of standard diesel.

More Info about this Invention:

[SLASHGEAR.COM][THEENGINEER.CO.UK]

Add Comment

We would be interested in knowing if the technique could be used to make chemical feedstock such as ethylene, propylene, butene, hexene.

Posted by Ron Lutz on February 20, 2019

Good day! We have only 1 question for the engineers of this project: How can there be economic sense in the processing of polymer granules into fuel? In order to produce fuel, it is necessary to first collect, sort, grind raw materials from the landfill, wash it, and produce a granule from it. And only then this granule can be processed into fuel, which will not meet quality standards. The technology developed by our group of engineers is very different from the technology shown by you. The technology allows to produce finished products directly from polyethylene flex or PET (bottles). Product samples were obtained - powder, granule, monolithic polymer, technical lubricant (several grades), several grades of polymer fiber with different properties, wax, composite materials based on PET, conductive current polymers. We are looking for contact with a company that is interested in cooperation. Regards, Oleg!February 21, 2019

Posted by Oleg Rebrov on February 21, 2019

fields are required.

Comments

We would be interested in knowing if the technique could be used to make chemical feedstock such as ethylene, propylene, butene, hexene.

Posted by Ron Lutz on February 20, 2019

Good day! We have only 1 question for the engineers of this project: How can there be economic sense in the processing of polymer granules into fuel? In order to produce fuel, it is necessary to first collect, sort, grind raw materials from the landfill, wash it, and produce a granule from it. And only then this granule can be processed into fuel, which will not meet quality standards. The technology developed by our group of engineers is very different from the technology shown by you. The technology allows to produce finished products directly from polyethylene flex or PET (bottles). Product samples were obtained - powder, granule, monolithic polymer, technical lubricant (several grades), several grades of polymer fiber with different properties, wax, composite materials based on PET, conductive current polymers. We are looking for contact with a company that is interested in cooperation. Regards, Oleg!February 21, 2019

Posted by Oleg Rebrov on February 21, 2019

Add your Comment:

[LOGIN FIRST] if you're already a member.fields are required.

Show 2 Comments