Greener and Cheaper Metal Patterning Method

Aug-18-19

An innovative new method of creating conductive pathways is safer for the environment and potentially much more affordable.

Aug-18-19

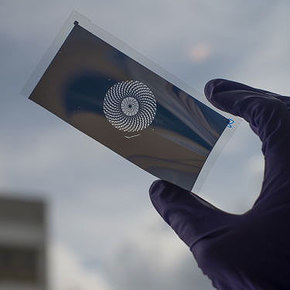

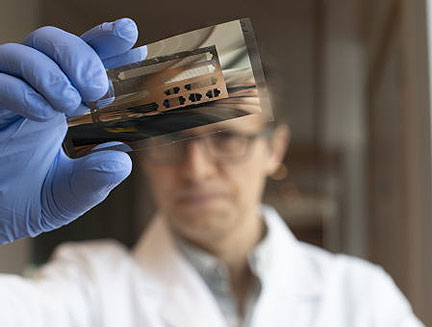

An innovative new method of creating conductive pathways is safer for the environment and potentially much more affordable.Typically, conducting lines in metal for electronic devices are made by removing the metal using harsh chemicals and expensive inks. As a safer alternative, the technique from the team at Warwick University was built on the discovery that silver and copper will not condense on thin films of particular highly-fluorinated compounds when the metal is deposited by simple thermal deposition.

Armed with that knowledge, the team’s new technique relies on printing a negative pattern where connections are not needed, and then laying down the metal in the remaining area where the coating is not applied. The result is a successful, conductive pattern that leaves the remaining metal surface uncontaminated—an important distinction for the next generation of sensors.

More Info about this Invention:

[WORLDINDUSTRIALREPORTER.COM][WARWICK.AC.UK]

Add Your Comment