New Conductive Ink Process Leads to Fitted Wearables

Jun-28-15

A new, single-step process for printing conductive ink on cloth could open the door to wearables able to monitor heart rate or other vitals.

Jun-28-15

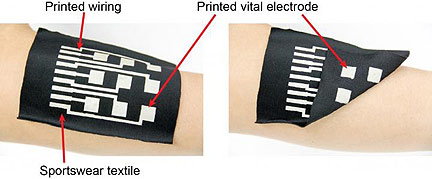

A new, single-step process for printing conductive ink on cloth could open the door to wearables able to monitor heart rate or other vitals.Created by a team from Tokyo University, the technology involves a specific ink that allows electrodes and wires to be printed on both sides of the textile in a single step. The resulting cloth is more flexible and softer than current printed electronics, and will continue to conduct electricity even when stretched up to three times its length.

Although there are other electronic fabrics in development, the fabric from the Japanese team is the first that is stretchy enough to fit tightly to the skin, which makes it useful for body monitors.

Image: 2015 Someya Laboratory

Electrodes, wires, and via holes can be printed by a single step printing process. The muscle activity sensor was produced by printing once on each side of the material's surface.

More Info about this Invention:

[GIZMODO.COM][EUREKALERT.ORG]

Add Your Comment