Three Jaw Adjustable Wrench

Angus R. Campbell , Canada By designing the Three Jaw Adjustable Wrench I was able to envision a tool with superior grip but still keeping the number of components to a minimum. This would be important to any potential manufacturer by keeping the tooling requirements to a minimum and still producing a device that could be marketable and function as the design intended. It was conceived during a plumbing expedition which involved a leak, water and angry spouse who couldn't wait to clean up the mess. It was during this emergency I realized that a multiple function tool which could grip both a pipe and a hex nut was vital to speed up the job at hand. Unfortunately the tool wasn't designed until after the mess and I still had to borrow a neighbors wrench.

By designing the Three Jaw Adjustable Wrench I was able to envision a tool with superior grip but still keeping the number of components to a minimum. This would be important to any potential manufacturer by keeping the tooling requirements to a minimum and still producing a device that could be marketable and function as the design intended. It was conceived during a plumbing expedition which involved a leak, water and angry spouse who couldn't wait to clean up the mess. It was during this emergency I realized that a multiple function tool which could grip both a pipe and a hex nut was vital to speed up the job at hand. Unfortunately the tool wasn't designed until after the mess and I still had to borrow a neighbors wrench.I am an Engineering Designer who likes to rethink anything from the layout of a house, a tool to the worlds energy supply. At present I am working in the Aerospace industry but I have extensive experience in the Marine Industry and it is there that I am applying my skills for my next project-a Wave Energy Converter-which operates across a very wide range of wave heights. I hope to have this onstream soon.

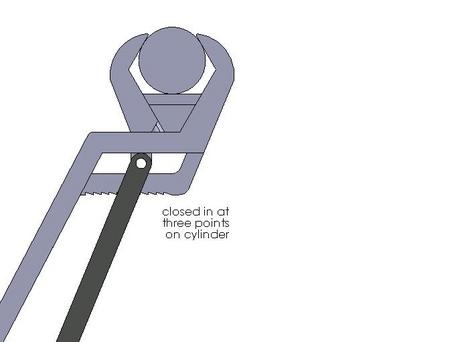

The Three Jaw Adjustable Wrench consists of five components assembled together as a wrench to enable the device to grip a hexagonal fastener on three sides or a round cylindrical object at three points for a stronger grip than conventional wrenches. The five components are The Main Handle, the Larger Slider, The Smaller Slider, the Pivoting Handle and a pin.

The Main Handle is angled (120 Degrees) on one end to fit the angle of a hexagonal fastener and is slotted for the Larger Slider to move across in a horizontal direction. Further along the main handle is a member connected in such a manner that it provides a guide for the end of the Larger Slider and on the opposing side, teeth along the edge which enable the Pivoting Handle to pivot and force the Sliding Member against the opposing side of a hexagonal fastener. As the Pivoting Handle rotates and pushes the Larger Slider horizontally, the Smaller Slider is forced along both the edge of the Sliding member and an edge of the Main Handle thus enclosing in on a third side of the hexagonal fastener. Both the Larger Slider and the Smaller Slider are connected with rounded slots to prevent disconnection as well as the Larger Slider and Main Handle. The pivoting Handle is connected to the Larger Slider by a pin and has a fork shaper which encompasses the toothed member. The device acts with a positive force (the harder one pushes the firmer the grip) along the full length of three sides of a nut or a cylindrical object. The advantages of the designs are the grip is along a full side of each griping side rather than at the corner which is where a regular wrench grips.

Next Story »