NO-SPILL OIL CONTAINER

Summary:For about the cost of a standard motor oil container, this container prevents spills:

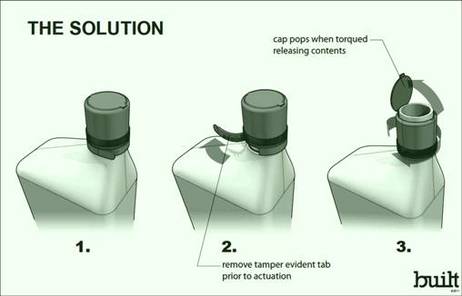

1. Tip the container upside-down over your valve cover opening.

2. Instead of removing the closure, tighten it!

3. The top of the closure pops open, dispensing your oil without a mess.

For small engines, may be re-sealed like a standard container - without popping the top.

Full Description:

The motor oil dispensing aspect of the invention design gives the end user two options:

1) If he or she requires just a small volume of oil for “topping up” an engine, the cap on the oil container may be unscrewed, and required amount of oil dispensed in the usual way into valve cover opening or other oil port. The cap may then be re-threaded and sealed onto the container for future use. In this case, the user does not take advantage of the special, dribble-proof feature of the design.

In the second option, the end user may be “changing” his or her vehicle oil, as many vehicle owners routinely do. In this case, the user will first remove the old oil, replace the oil filter, and re-seal the drain plug. He or she will then attempt to pour into the valve cover opening the usually 4 or 5 quarts of fresh oil required in most modern cars and small trucks.

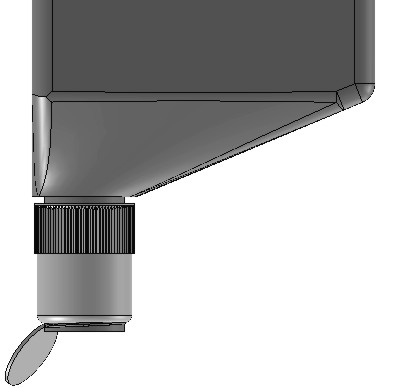

For our purposes here, let us assume the present invention has been incorporated into a 1 quart motor oil container including a closure or cap. Let’s further assume the container portion is blow-molded polyolefin - the current standard production method and material for this part. The cap is injection-molded polyolefin, also the current standard. A typical cap in a fluid-holding application often has a sealing liner made of a compressible or deformable material attached under the inside top of the cap to prevent leakage of the container contents once the cap is torqued down to specifications after filling in the factory. There are other, linerless sealing designs and options. Our design is able to make use of the same sealing methods as are the standards in the industry.

Having purchased oil sold in our new packaging, the end user will first, by hand, strip away a lower portion of the plastic cap. To those familiar, many 5 gallon plastic bucket lids have a similar feature; a small tab at the base of the cap, when pulled, will allow a thin strip of the polyolefin cap material to be torn away from the rest of the cap. This thin strip need not be completely removed - it may remain attached by a thickened portion at the end of the strip (to prevent littering, etc.). Ease of removal of the strip is determined by the shape and thinness of the plastic between the thin strip and the rest of the cap. Because the cap is injection-molded, these shapes and dimensional tolerances may be controlled tightly and reliably for our purposes.

Once the strip is removed adequately, the quart of oil with the still-attached cap is inverted into the engine’s valve cover opening where the fresh oil is typically poured. The cap is of a length and designed with sufficent gripping shape or surface so that, once inverted into the engine, the user may still reach and twist the cap easily with his or her fingers. Holding the rest of the oil container firmly, the user tightens the lid onto the container until the top of the lid pops open. The top of the lid has been so designed, with a sharp V-cut or similar perforation molded most of the way around the cap’s upper circumference, that force resulting from tightening the cap onto the container causes the material in the V-cut to fail, and this top portion of the cap to pop open. The V-cut is molded thin enough, and with tight-enough tolerances, that the cap does not leak, but that it rips away when so applied with minimal effort. The V-cut does not go all the way around the top portion of the cap, so that the top of the cap, as it opens, swings like a gate away from the container but remains attached to the rest of the cap and does not fall into the engine.

Oil pours into the engine with essentially no more restriction than a standard 1 quart oil container where the cap is normally removed to dispense the oil. Any sealing liner that may be used between the underside of the cap and the top lip of the container will be attached, either through adhesive or other attachment means such, that it remains attached to the swing-away portion of the cap and does not fall into the engine. When the 1 quart container is empty, the user removes and disposes of the container with the cap, liner and, in the preferred embodiment, the tabbed strip still attached. The user has never come into contact with liquid oil. There are no oily funnels to drip. It is a clean, simple dispensing process.

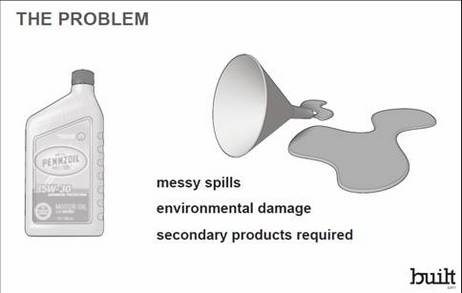

Problem this idea/invention addresses:

A modified motor oil container/closure which improves dispensing and prevents spills when changing oil.

Attached files:

Asking price: [CONTACT SELLER]

Available for consultation? Yes

Invention #11752

Date posted: 2012-05-07

« More Automotive Inventions