Cellulose 3D-Printing Material offers Organic Alternative

Jun-13-18

A new method of using cellulose as a 3D-printing material makes it possible to use the abundant material in large-scale manufacturing.

Jun-13-18

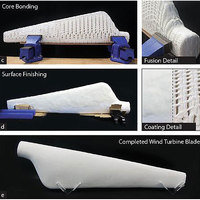

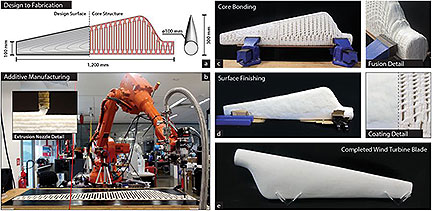

A new method of using cellulose as a 3D-printing material makes it possible to use the abundant material in large-scale manufacturing.For years, researchers have attempted to use cellulose in 3D-printing, but the material resisted scaling up and required high production costs. To overcome these obstacles, the team from the Singapore University of Technology and Design turned to FLAM (fungal-like adhesive materials). Inspired by the wall of the fungal-like oomycetes, FLAM is made up of plant cellulose and chitin, which the team combined in an industrial dough mixer to create enough of the material to print a 1.2 meter-long turbine blade.

According to SUTD Assistant Professor Javier Gomez Fernandez., FLAM production is “probably one of the most successful technological achievements in the field of bioinspired materials” to date.

More Info about this Invention:

[3DPRINTINGINDUSTRY.COM][SCIENCEDAILY.COM]

Add Your Comment