Shaping Lenses with Liquid and Magnets

May-21-19

An innovative lens-shaping technique relies on movable magnets to create custom lenses.

May-21-19

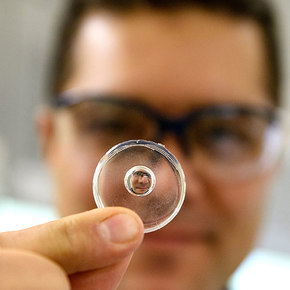

An innovative lens-shaping technique relies on movable magnets to create custom lenses.Developed by teams from Ohio State University and Washington state, the new technology replaces complex and costly metal molds with magnets and iron particles. The team inserted tiny iron particles into a drop of liquid surrounded by magnets, then poured the plastic material used to make lenses on top. The application of a magnetic field caused the droplet form into a cone—creating a mold for the plastic, which can then be cured. The magnetic field can also be manipulated to create lenses with different sizes.

According to team leader Lei Li, “We brought the concept of interfacial tension to the field of optics by introducing an innovative controllable liquid mold. This novel process allowed us to regulate the shape of a magnetic drop and to create lenses without having to fabricate expensive molds.”

More Info about this Invention:

[CO.UK][NEWS.WSU.EDU]

Add Your Comment