Method of Blow Molding a Bulk Metallic Glass

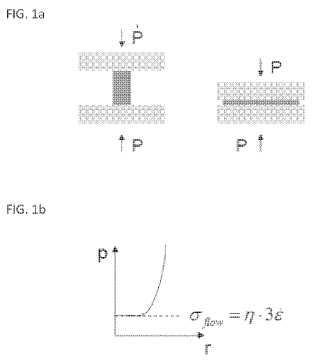

A very low pressure gas or blow forming process for shaping a bulk metallic glass (BMG) in its supercooled liquid state that avoids the fractional stick forces experienced by conventional shaping techniques by engineering the expansion of a pre- shape or parison of BMG material such that substantially all of the lateral strain required to form the final article is accomplished prior to the outer surface of the parison contacting the surface of the shaping apparatus is provided. The capability offered by the inventive shaping process to avoid the frictional forces exerted by the shaping apparatus surface allows for the formation of precision net-shape complex multi-scale parts and components using processing conditions inaccessible by conventional processes.Attached files:

Patents:

WO 2,009,070,701

Inventor(s): SCHROERS JAN [US]; HODGES THOMAS MACKENZIE [US]

Type of Offer: Sale

« More Manufacturing Patents