Method for the production of a mold insert for a casting mold for injection molding, comprises applying a powder forming material in a thin layer on a base surface and melting a defined area of the la

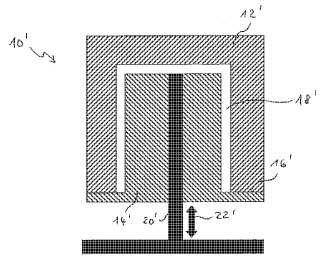

The method for the production of a mold insert for a casting mold (10') for injection molding, comprises applying a powder forming material in a thin layer on a base surface, melting a defined area of the layer with a high energetic beam through thermal power, applying a further thin layer of the powder forming material on the prior thin layer and completely constructing the mold insert, where a porosity is produced in the form insert. The high energetic beam is laser beam. A compressed gas channel communicating with the porosity is introduced in the mold insert. The method for the production of a mold insert for a casting mold (10') for injection molding, comprises applying a powder forming material in a thin layer on a base surface, melting a defined area of the layer with a high energetic beam through thermal power, applying a further thin layer of the powder forming material on the prior thin layer and completely constructing the mold insert, where a porosity is produced in the form insert. The high energetic beam is laser beam. A compressed gas channel communicating with the porosity is introduced in the mold insert. The porosity is produced in which the defined area of the layer of the powder forming material is melted by a radiation energy applied against the area to be melted, reduced per unit area. The porosity is formed through a channel formed in the mold insert. The adjoining layers of powder forming material are not melted by an area limiting the area to be melted. The non-melting area communicates the adjoining area so that a channel is formed in the mold insert. The porosity is produced in the mold insert that extends itself through a surface of the mold insert equipped with the casting mold. After the production of the mold insert by laser beam, the surface of the mold insert is subjected by an external bore extending to the porosity of the mold insert for the formation of cast part produced with the casting mold. The bore has a diameter of less than 20 mu m. An INDEPENDENT CLAIM is included for a mold insert for a casting mold.Attached files:

Patents:

DE 102,009,016,110

Inventor(s): BECKER UWE [DE]; EMMELMANN CLAUS [DE]; VOGEL HENDRIK [DE]

Type of Offer: Sale

« More Engineering - Industrial Patents