Magnetorheological Materials, Method for Making, and Applications Thereof

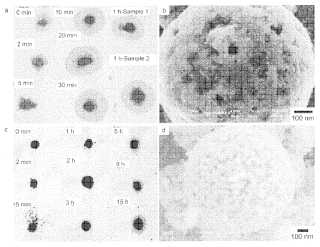

A magnetorheological material comprises a magnetic particle and a ceramic material, wherein the magnetorheological material is in a dried form and further wherein a portion of the ceramic material is in the form of a nanocrystalline coating over the entire exterior surface of the magnetic particle and another portion of the ceramic material is in the form of a free nanocrystal. A magnetorheological material comprises a magnetic particle having a ceramic material coating over an external surface thereof as a result of a coating process, and a free nanocrystal of the ceramic material in the form of a residual by-product of the coating process. A sol-gel process for making a magnetorheological product comprises providing a sol of a desired ceramic coating material; combining a desired quantity of carbonyl iron (CI) particles with the sol to coat the CI particles with the ceramic coating material; creating a resulting quantity of nanocrystalline ceramic material-coated CI particles and a quantity of free nanocrystals of the ceramic material; and, drying the resulting quantity of coated CI particles and free nanocrystals to a moisture content equal to or less than 2 wt %.Attached files:

Patents:

US 20,100,171,065

Inventor(s): SHEN RUI [US]; YANG HONG [US]; SHAFRIR SHAI N [US]; MIAO CHUNLIN [US]; WANG MIMI [US]; MICI JONI [US]; LAMBROPOULOS JOHN C [US];

Type of Offer: Licensing

« More Material Science Patents