Apparatus and Method for Preform Relaxation and Flow Control in Liquid Composite Molding Processes

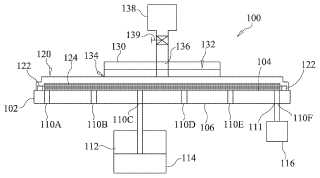

A vacuum-induced injection molding apparatus is disclosed. The apparatus includes a tool surface having an injection port extending therethrough. A flexible film extends over and is sealingly coupled to the tool surface. The flexible film comprises an outer surface and an inner surface such that the flexible film inner surface and the tool surface define a volume. A vacuum chamber is sealingly coupled to the outer surface of the flexible film. A vacuum port is in fluid communication with the volume. A method of injection molding a polymer matrix composite is also disclosed.Attached files:

Patents:

US 20,100,072,677

Inventor(s): ALMS JUSTIN B [US]; GLANCEY JAMES L [US]; ADVANI SURESH G [US

Type of Offer: Licensing

« More Manufacturing Patents