Composites with Graded Microstructures for Orthopedic Implants and Bone Tissue Engineering

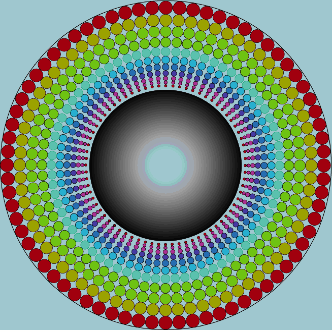

An inorganic scaffold with a strong, dense core and graded porosity is infiltrated with different polymers to provide a gradient in solubility. Porosity is greatest at the surface, promoting cell attachment and formation of new tissue. APPLICATIONS OF TECHNOLOGY:- Orthopedic implants with bone-like mechanical properties - Scaffolds for bone tissue engineering - Scaffolds for in vitro cell growth

ADVANTAGES:

- Allows fabrication of materials with tailored properties never before possible - Increases implant integration with bone through greater surface porosity - Promotes rapid bone growth - Provides strength with a dense inner core - Generates materials with controlled gradients of porosity and solubility

ABSTRACT:

The first generation of biomaterials was developed from materials used in engineering applications. Unlike bone, these biomaterials cannot self-repair or adapt to changing physiological conditions. Most implants for bone replacement are metals that are stiffer and stronger than bone, such as titanium and stainless steel. These implants shield the surrounding skeleton from normal stresses and discourage new bone growth, causing the implant to loosen over time as the surrounding bone is resorbed. Degradable supports made of lactic and glycolic acid polymers are now common, but their use is limited to non-load bearing applications such as broken jaws and fractured skulls. New biomaterials are needed with properties similar to natural bone.

Tony Tomsia, Eduardo Saiz, and colleagues at Berkeley Lab have developed a new generation of organic/inorganic composite materials that mimic the structure and composition of natural bone. Inorganic components provide stiffness and strength while the organic components increase durability. To function like natural bone, these new composites supply a porous matrix that promotes rapid bone ingrowth while possessing sufficient strength to prevent crushing under physiological loads during integration and healing.

New processing techniques—such as freeze-casting, stereolithography, and 3-D printing—have also been developed to provide biomaterials with a wide range of solubilities (bioresorption rates) and mechanical properties. These biomaterials are also intended to be partially or completely resorbed and replaced by bone from the host. Scaffold fabrication with these tailored microstructural properties has not been possible until now.

Using these techniques, materials with a strong, dense core can be fabricated with increased porosity at the surface to facilitate cell attachment. This capability of using flexible processing techniques to generate materials with different gradients in solubility and porosity is a key component of this technology.

Attached files:

Inventor(s): Tony Tomsia, Eduardo Saiz

Type of Offer: Licensing

« More Material Science Patents