Conductive Carbon Coatings for Electrode Materials

APPLICATIONS OF TECHNOLOGY:Carbon coatings for LiFePO4 electrode materials used in lithium ion or lithium metal batteries for high power applications such as power tools and hybrid electric vehicles

ADVANTAGES:

Increases high power discharge without sacrificing energy density Low cost and excellent durability Easily integrated into existing manufacturing processes

ABSTRACT:

Marca Doeff, Robert Kostecki, and colleagues at Berkeley Lab have developed improved carbon coatings for LiFePO4 materials used in lithium ion batteries. The coatings enhance electrochemical performance without sacrificing the energy density of the battery.

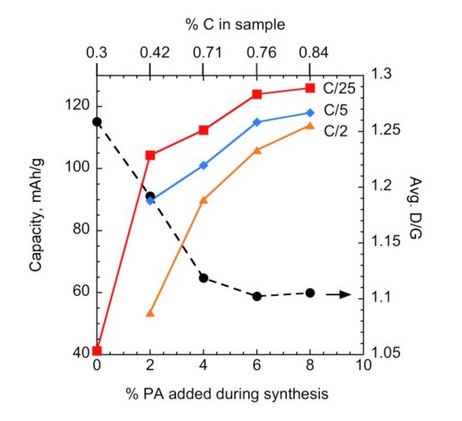

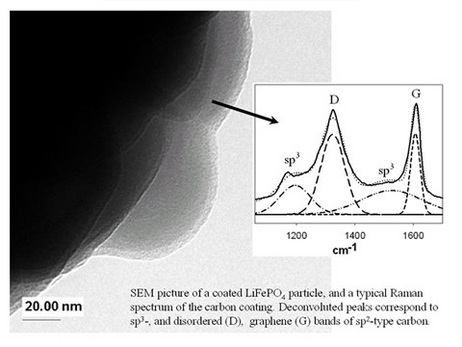

The Berkeley Lab researchers have produced very thin carbon coatings ( <10 nm) on non-conductive LiFePO4 particles, increasing the electronic conductivity of the composite as much as six orders of magnitude compared to the native material. The low carbon content (<2 wt. %) allows high power operation without compromising energy density. The coatings are extremely durable; no evidence of degradation was found after more than 100 full charge-discharge cycles. The process involves co-synthesizing LiFePO4 and carbon by adding optimal amounts of specific organic and organometallic pecursors to the reaction mixture prior to calcinations. The method is both low cost and highly compatible with existing LiFePO4 manufacturing processes.

While LiFePO4 displays stability, low toxicity, low cost, abuse tolerance, and excellent electrochemical characteristics, its low intrinsic electronic conductivity limits the electrochemical performance at high charge-discharge rates. To date, carbon coatings have improved the discharge performance of these batteries but the higher the carbon content, the lower the battery’s energy density. Moreover, current practices of adding organic or polymeric precursors during LiFePO4 synthesis produce poor quality carbon that has lower electronic conductivity. Key to the invention was the discovery by the Berkeley Lab team that highly-graphitic conductive carbon coatings on LiFePO4 improve material utilization and power performance at a given discharge rate compared to those coated with more disordered or amorphous carbon. Doeff and Kostecki exploited this fact by applying a technique used in the steel industry called “dusting”, otherwise referred to as catalytic graphitization, to precipitate out graphitic carbon at the low temperatures that are typical for producing phase-pure LiFePO4.

The Berkeley Lab invention is applicable to LiFePO4 electrode materials used in lithium ion or lithium metal batteries for high power applications such as power tools and hybrid electric vehicles.

Attached files:

Inventor(s): Marca Doeff, Robert Kostecki

Type of Offer: Licensing

« More Energy Patents