Producing a beverage with ethanol content, comprises processing malt to wort, fermenting the wort using maltose-negative yeast, supplying raw fruit next to the malt, and adding lactic acid and aroma o

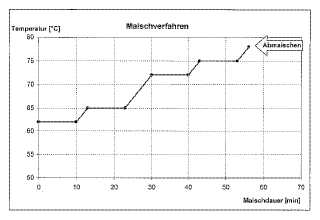

The method comprises processing malt to a wort, fermenting the wort using maltose-negative yeast, supplying a raw fruit (1-50%) next to the malt (99-50%), where the raw fruit portion is dependent of the malt portion and the portion of raw fruit and malt together yields 100%, adding lactic acid during mixing, adding aroma or ascorbic acid to the fermented wort, filtering the fermented wort, carbonating the fermented wort, and pasteurizing the beverage. The malt contains barley malt (0-100%), rye malt (0-50%), 0-20% of color malt, aroma malt and/or melanoidin malt, and/or roasted malt (0-10%). The method comprises processing a malt to a wort, fermenting the wort using a maltose-negative yeast, supplying a raw fruit (1-50%) next to the malt (99-50%), where the raw fruit portion is dependent of the malt portion and the portion of the raw fruit and malt together yields 100%, adding lactic acid during mixing, adding aroma or ascorbic acid to the fermented wort, filtering the fermented wort, carbonating the fermented wort, and pasteurizing the beverage. The malt consists of barley malt (0-100%), rye malt (0-50%), 0-20% of color malt, aroma malt and/or melanoidin malt, and/or roasted malt (0-10%). The raw fruit is barley. The maltose-negative yeast is yeast of the species Saccharomycodes ludwigii. A part of the wort is fermented with a Lactobacillus for producing lactic acid. Before processing the malt to the wort, the malt is rolled by a rolling mill, which has following dimensions for the respective malt types such as pilsner malt (1.7 mm), barley (1.0 mm), rye malt (0.7 mm) and color malt (1.7 mm). The method further includes soaking the barley in water before grinding, and adding enzyme for the decomposition of polymers. An INDEPENDENT CLAIM is included for a beverage with an ethanol content of below 0.5 vol.%.Attached files:

Patents:

DE 102,009,005,971

Inventor(s): METHNER FRANK-JUERGEN [DE]; KUNZ THOMAS [DE]

Type of Offer: Sale

« More Food Science Patents