Polymer Films Lead to Flexible Heat Sinks

May-03-19

Polymer films able to conduct heat without trapping it could lead to lighter cars and electronics.

May-03-19

Polymer films able to conduct heat without trapping it could lead to lighter cars and electronics.Developed by a team from MIT, the films are made up of a common polyethylene powder that has been dissolved in a solvent that causes the material’s coiled molecular knots to straighten. That solution was then sent through a customized device that smoothed the tangled chains even more and delivered the liquid to a cooling plate, where it was stretched into a thin film. According to the researchers, the straightened molecular chains transfer thermal energy much more efficiently than their tangled counterparts, resulting in a thin, flexible material able to conduct heat a 60W per meter per kelvin (compared to steel at 15W).

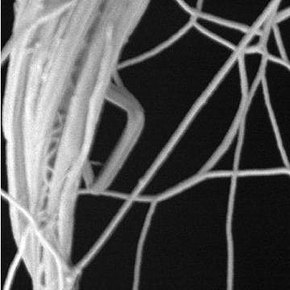

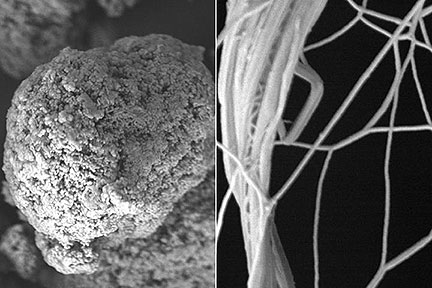

Image: Gang Chen et al - By mixing polymer powder in solution to generate a film that they then stretched, MIT researchers have changed polyethylene’s microstructure, from spaghetti-like clumps of molecular chains (left), to straighter strands (right), allowing heat to conduct through the polymer, better than most metals.

More Info about this Invention:

[ELECTRONICSWEEKLY.COM][NEWS.MIT.EDU]

Add Your Comment