Printing 3D Metal with Liquid Inks

Jan-14-16

A new method of printing 3D materials uses liquid inks to offer a lower cost, faster, and more uniform result.

Jan-14-16

A new method of printing 3D materials uses liquid inks to offer a lower cost, faster, and more uniform result.Currently, most processes for 3D printing metals rely on a powerful energy source (such as a laser) to fuse a bed metal powders together. Not only is this process time-consuming, it is also limited by the types of metals that can be used.

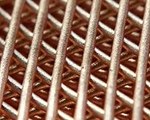

In contrast, the technology developed by a team from Northwestern University skips the metal power bed and laser in favor of a liquid ink made of metal powder, solvents and an elastomer binder. Using this mixture, the team was able to print a dense structure using the simple process of extruding the ink through a nozzle at room temperature. Once extruded, the liquid material will fuse with previously extruded materials and solidify, allowing large objects to be created and handled relatively quickly. Once the structure has been built, it can be fused in a simple furnace using the sintering process.

Image Credit: Northwestern University - A copper lattice structure created using the new process.

More Info about this Invention:

[GIZMAG.COM][MCCORMICK.NORTHWESTERN.EDU]

Add Your Comment