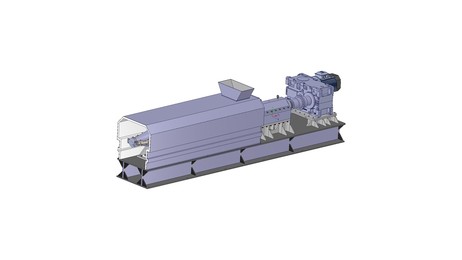

Process and Apparatus for the Production of a Solid Fuel from Combustible Wastes

The present invention relates to a machine for manufacturing solid recovered fuel, to a process for obtaining solid recovered fuel. The method developed and patented by Sacave allows the transformation of non-hazardous waste into homogeneous SRF or new material systems, reducing the pre-treatment of this, as the particle size reduction and the reduction of moisture. The process takes place in a single phase of one hour's duration, within a range of practically zero emissions and does not require the addition of any chemical substance.PROCESSABLE WASTE:

Our technology is capable of processing all types of organic and inorganic waste to transform it into fuel or a new material systems. Only non-hazardous waste is suitable for this process (its composition must not contain one or more elements that may be harmful to health or the environment).

Agricultural Waste

Industrial Waste

Urban Waste

Forest Waste

The products obtained with our method have the following features:

The retrieved compound is homogeneous, both in composition and moisture, particle size and density.

Minimum moisture content.

High calorific value.

High density.

Programmable physicochemical characteristics.

Initial malleability.

Materials which are not processable:

Stone materials.

Ferrous and non-ferrous metals.

Products containing substances dangerous to health or the environment.

Inert materials.

The method and apparatus patented sacave allows processes non-hazardous waste and produces homogeneous fuel (SRF). These come from different rejection fractions flows : urban, industrial, agricultural, and forestry. The energy consumption of the process varies between 2 and 5 of the gross energy contained in the homogeneous SRF retrieved and processed waste get a LCV-wet based 2 to 4 times greater than non-processed waste. Our method does not require a certain particle size reduction, or a reduction in the rate of humidity of the waste to be processed.

ADVANTAGES OF OUR NEW SRF:

- Reduced costs of production: Elimination of moisture-reduction pretreatments.

- The economic viability of the production process allows it to be compared with fossil fuels.

- Allows the creation of an alternative market to the conventional sources of fuels.

- Reduction of landfills and creation of new business lines.

- Ideally suited to integrate in the new technologies of energy production: During the process of energy generation, the amount of oxygen and the temperature the furnaces and boilers need can be programmed for high electrical performance thanks to the quality of homogeneity developed in the fuel.

- Numerous environmental and social benefits.

REPLACEMENT OF FOSSILS FUELS:

- Reduction of imported fuels, greater security of supply and stability of costs.

- Higher Calorific Value, over 20% more.

- Much lower humidity content.

- Reduction of ashes.

- Valorisation possibility in thermal power stations (carbon and biomass) with minimum adaptation costs.

- Much lower pollutant emissions and possibility of marketing GHGs emissions.

- Possibility of obtaining subsidies from the State, due to its consideration as alternative renewable energy.

POTENTIAL MARKET OF THE NEW SRF IN EUROPE:

- At the seminar of ERFO (European Recovered Fuel Organisation) which was held in Dublin on October 20, 2011, the European potential to produce SRF was estimated in 70 million tons.

- Europe last year produced 12 million tons of SRF, only a 17% of the maximum amount that can be recovered. The country that produced the most SRF was Germany with 6 million tones in 2010.

- Sacave estimates that with the aplication of the new method, the SRF made with the waste of the urban treatment plants would increase up to 39 millions tons approximately, without taking into account the other kind of waste (industrial, forestal, agriculture, etc.).

GLOBAL VISION OF THE BUSINESS:

- Maximizing the use of available resources.

- Possibility of reducing the consumption of fossil fuels.

- Reduction of landfills, maximum profitability.

- Technological advantage: positioning as worldwide leaders.

- Pioneers in a strategic sector for the society.

SUMMARY:

- The method gives the processed waste new physico-chemical properties, obtaining a new product with an AR LHV (All moisture counted, lower heating value) from two to four times greater than that of the unprocessed waste.

- The energy expenditure of the process is only between 2% and 5% of the gross energy obtained.

- Waste does not require any pre-treatment of humidity or grain size reduction.

- The produced fuel is homogeneous, allowing to define the parameters regulating combustion, in order to obtain the highest percentage possible of the energy contained in the fuel (highest efficiency is obtained), and avoiding incomplete combustions and the generation of dioxins and furans.

- CO2 emissions corresponding to the biogenic fraction of the produced fuel are counted as neutral.

- The application of the method globally would allow to reduce by 30% the CO2 emissions from landfills into the atmosphere.

Attached files:

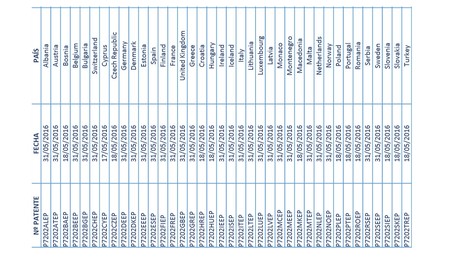

Patents:

EP 27,114,111 issued 2015-05-21 [MORE INFO]

Type of Offer: Sale or Licensing

Asking Price: US$127,000,000

« More Waste Management Patents

« More Recycling Patents