Three Dimensional Structure and Its Manufacturing Method

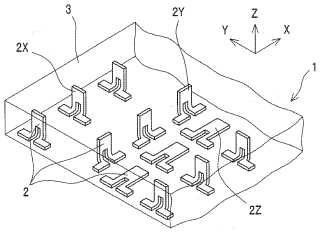

A plurality of micro three-dimensional structure elements each having a movable structure fixed on a sacrifice layer, and fixation portions of the micro three-dimensional structure elements for the sacrifice layer are arranged into a film-like elastic body, and then the sacrifice layer is removed. Thus, a three-dimensional structure in which the individual micro three-dimensional structure elements are arranged independently of one another within the elastic body is manufactured.The present invention relates to a structure, as well as its manufacturing method, formed three-dimensionally by using MEMS (Micro Electro Mechanical Systems) technology or NEMS (Nano Electro Mechanical Systems) technology. In particular, the invention relates to a three-dimensional structure, as well as its manufacturing method, in which micro three-dimensional structure elements having a movable structure are arranged in an elastic body.

The tactile sensor 501 having such a conventional structure as described above is formed through the steps of two-dimensionally forming each cantilever 502 as a thin-film member on an SOI wafer that is to become the substrate member 503, then forming a cantilever structure by etching or other process, thereafter performing such processes as erecting the cantilever structure by using a magnetic field or other force or method, and finally making the cantilever structure embedded in the film-like elastic body 504 that is formed from PDMS. Accordingly, in the state that the structure is embedded within the film-like elastic body 504, the substrate member 503, to which the individual cantilevers 502 are fixedly placed, is inevitably present.

When such a tactile sensor 501 is set for use on a curved surface such as a surface of a robot hand, the presence of the substrate member 503, which is a hard material, gives limitations of the use such as the placement of the tactile sensor 501 on curved-surface portions.

Therefore, an object of the present invention, lying in solving these and other issues, is to provide a three-dimensional structure, as well as its manufacturing method, in which micro three-dimensional structure elements each having a movable structure formed by using the MEMS technology or NEMS technology are placed within a film-like elastic body, the three-dimensional structure being capable of effectively utilizing the flexibility of the film-like elastic body while the operation of the movable structure is improved in smoothness.

Attached files:

Patents:

US 20,110,014,741

Inventor(s): SHIMOYAMA ISAO [JP]; MATSUMOTO KIYOSHI [JP]; HOSHINO KAZUNORI [US]; NODA KENTARO [JP]; HACHITANI SHUJI [JP]; YOSHIDA HIDEHIRO [J

Type of Offer: Sale

« More Engineering - Structural Patents