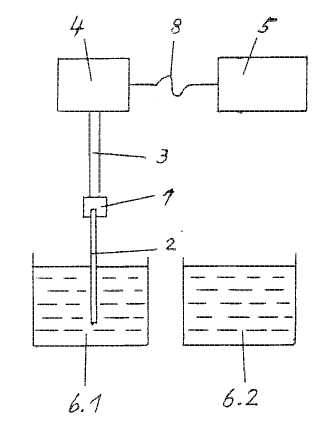

Measuring amt. of contamination in soft solder bath - by converting sonic pulses produced in metal probe dipped into bath into electrical pulses and plotting curve of phase summation against time

Method of quantitatively and qualitatively determining the degree of metal impurity in a soft soldering bath consists of monitoring the sonic impulses emitted as an intermetallic phase grows on the surface of a solderable metal (2) which is in contact with the bath (6.1). The sonic impulses are transferred via the clamp device (2) and coupling rod (3) to a vibraiton receiver (4) which converts the pulses to electrical pulses and then transfers these to evaluation device (5) via covered cable (8). The summation of the pulses against time is plotted and the resultant curve compared with standard curves to produce an impurity value for the bath. USE/ADVANTAGE - Determines the Cu impurity in a soft solder bath. The bath can be tested in situ with any sample being removed. The test involves low technical instrument expenditure and gives high accuracy.Attached files:

Patents:

DE 4,035,768

Inventor(s): HILBIG UWE DIPL ING [DE]; SCHEEL WOLFGANG PROF [DE]; WITTKE KLAUS PROF [DE]

Type of Offer: Sale

« More Metallurgy Patents

« More Diagnostic Patents